magnetic materials materials according DIN 17410 respectively DIN IEC 60404 8 1

In this section you will find the most common magnetic materials with their properties and manufacturing processes. This summary of the magnetic materials should give you a first overview and you also like to use the links to the quality values, the different types of magnetization and the application examples . Do not hesitate to contact us , we will gladly

advise you to find the right magnetic material or the right magnet system for your application.

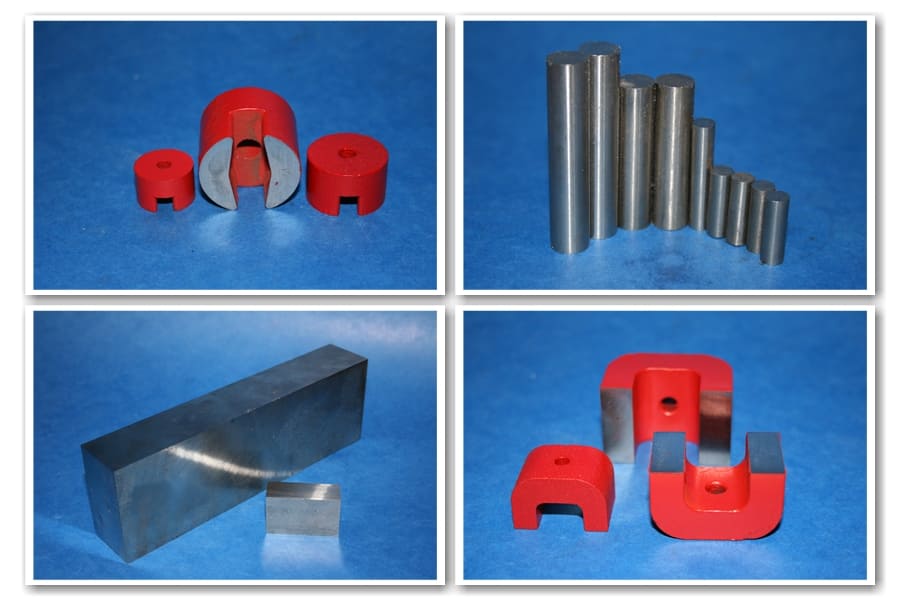

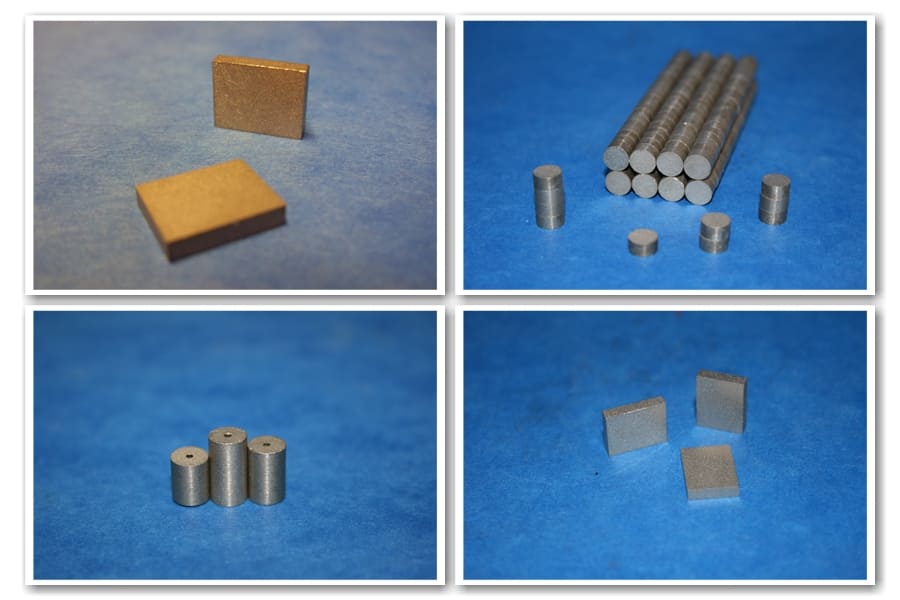

Aluminum-Nickel-cobalt (AlNiCo)

properties:

- High temperature resistance up to 500 °C

- low temperature coefficient

- Good corrosion resistance

- high remanence

- Low energy densities and low coercivities

- Highest mechanical stress

manufacturing process:

The Own AlNiCo-production in Bitterfeld-Wolfen is done by casting. (Technology of alnico cast magnet manufacture)

![]()

Made in Germany

sintering

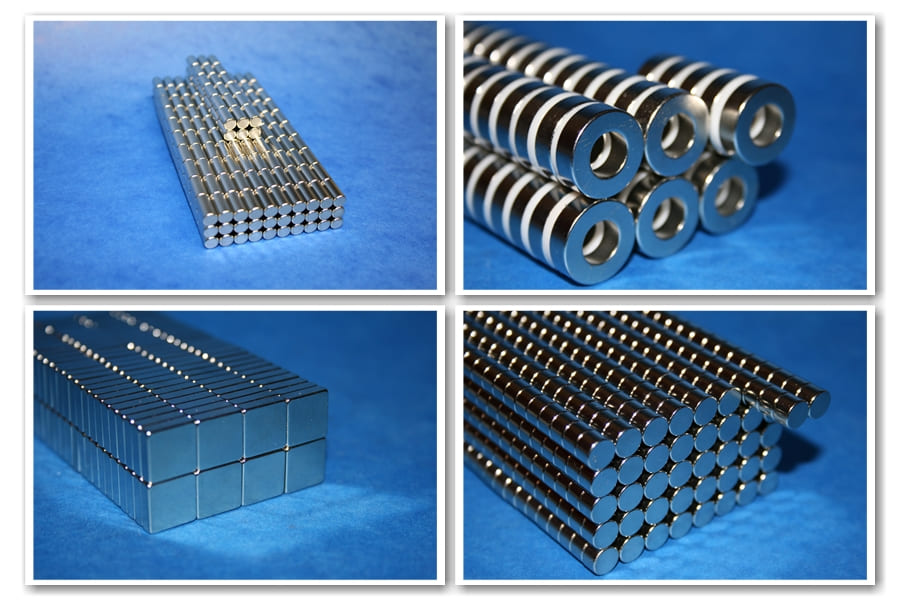

Neodymium-Iron-Boron (NdFeB)

properties:

- Highest energy densities

- high coercivities

- Low to moderate temperature resistance

- high temperature coefficient

- low corrosions resistance , surface coating is required

Samarium-Cobalt

(SmCo5 /Sm2 Co17)

properties:

- High energy densities

- highest coercivities

- Good temperature resistance up to approximately 300 °C

- medium temperature coefficient

- medium corrosions resistance

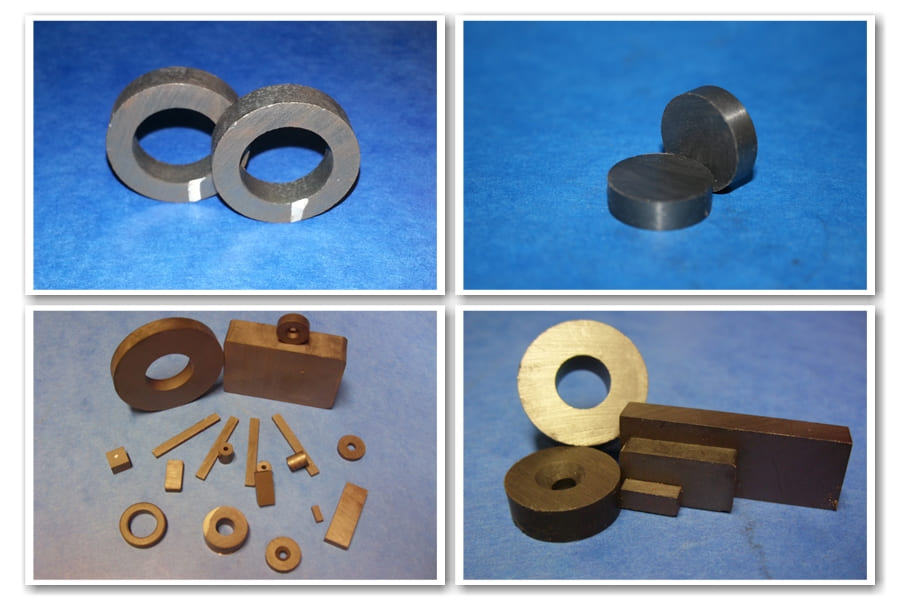

Hard ferrite (Barium- and Strontiumferrite)

properties:

- High coercivities

- moderate temperature resistance

- Low energy densities

- high temperature coefficient

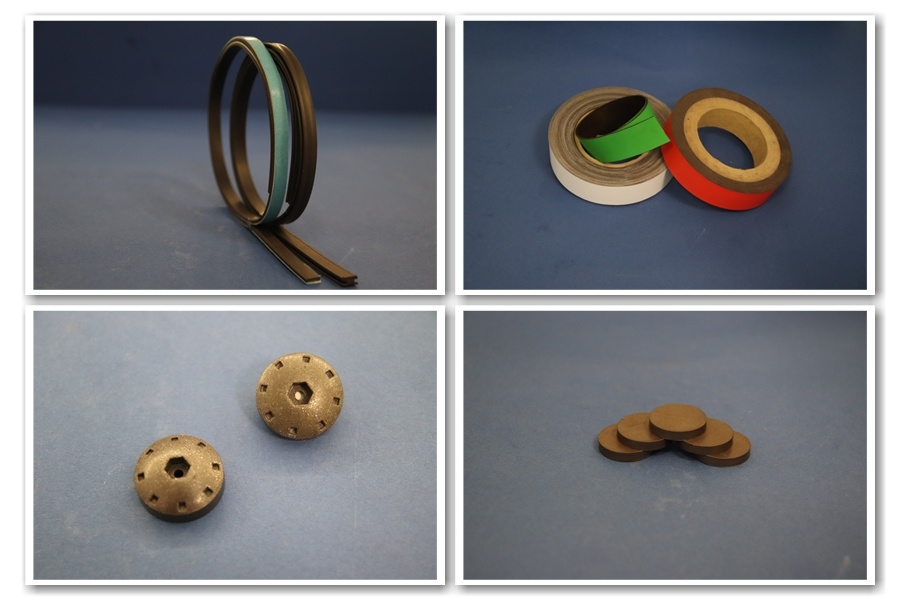

Plastic bonded magnets

properties:

- Manufacturing very flexible

- Considerable magnetic properties depending on the basic magnetic material

- To some extent flexible and easy to process

- Low temperature resistance

manufacturing process:

Feeder casting

extrusion

compression or calendering

The only cast magnet manufacturing in Germany

Delivery of all commercially available magnetic materials

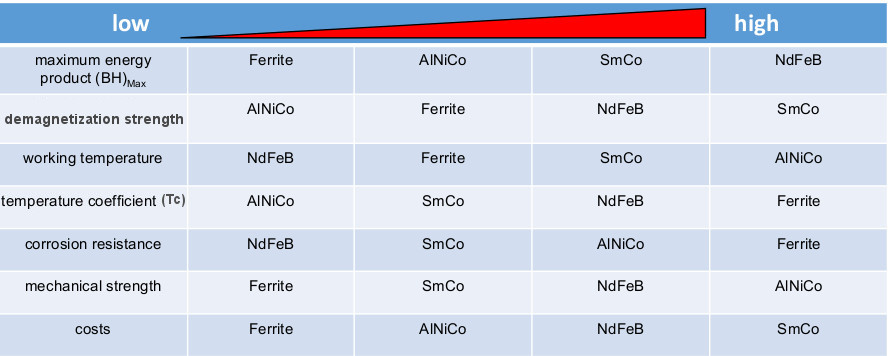

Comparison of magnetic materials